Inspection robots operate in tight spaces and harsh environments, often equipped with rotating cameras and sensors that require continuous rotation. To maintain reliable transmission of power […]

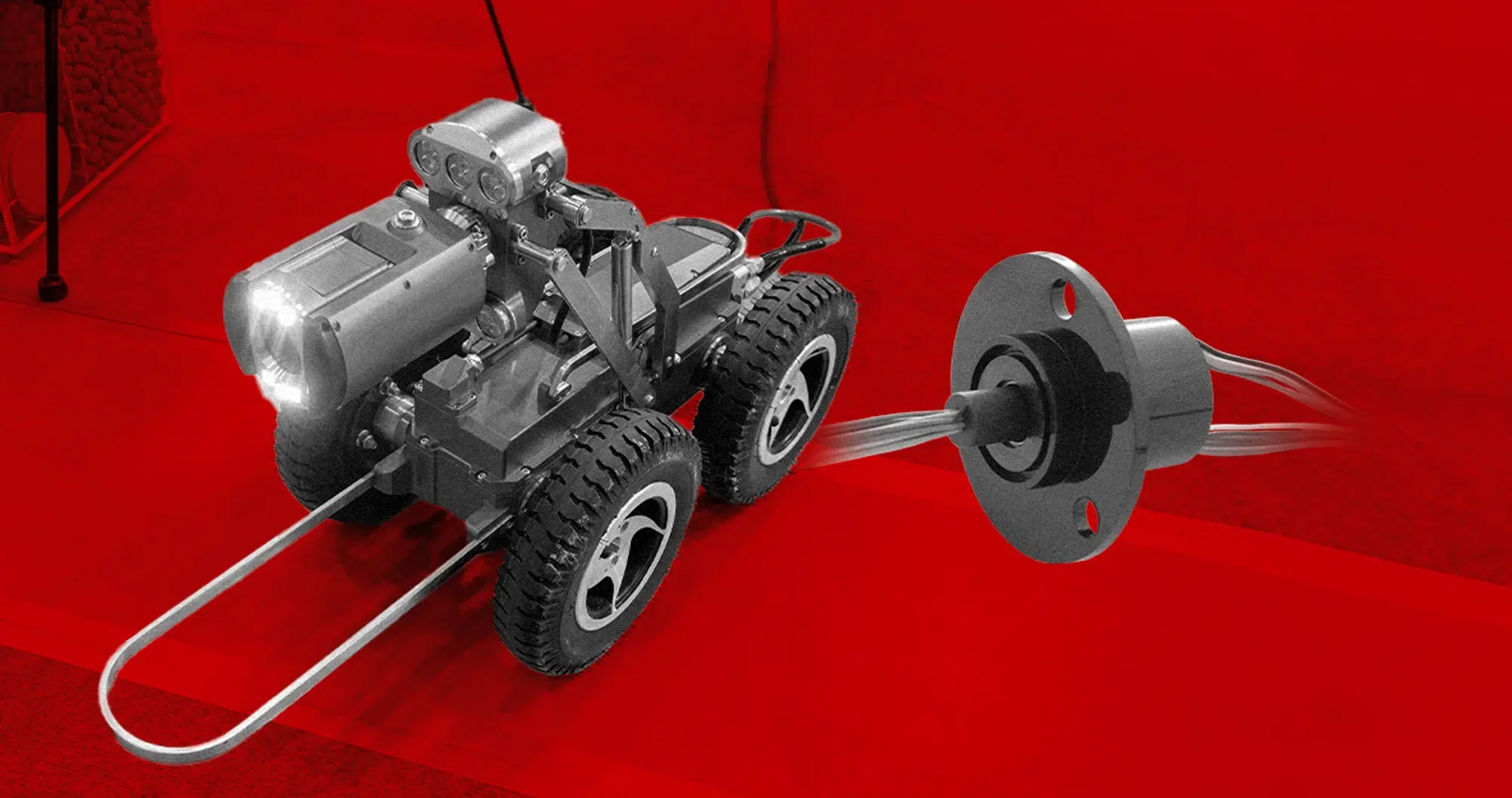

Inspection robots operate in tight spaces and harsh environments, often equipped with rotating cameras and sensors that require continuous rotation. To maintain reliable transmission of power and data between rotating and stationary parts, slip rings are essential components.

This article explains why slip rings are essential for inspection robots, highlights key features to consider, and helps you choose the right slip ring model. The focus is on Servotecnica’s SVTS A Series slip rings, widely used in cable reels and robotic cameras, with an emphasis on the SVTS A 06, which is ideal for camera applications.

Why Are Slip Rings Important for Inspection Robots?

When selecting the best slip rings for inspection robots, several key characteristics must be considered to ensure optimal performance:

1. Compact Size

Inspection robots, especially those designed for confined spaces such as pipelines or narrow entry points, require slip rings with a small footprint. Compact slip rings help maintain the robot’s slim profile without compromising performance.

2. Low Electrical Noise

High-definition video and sensitive sensor data require clean signal transmission. Slip rings with low electrical noise minimize interference, ensuring accurate, high-quality data and video feeds.

3. High Rotational Life

Inspection robots often perform thousands of rotations during operation. Slip rings must be highly durable and capable of withstanding continuous or repetitive rotational motion over long service periods.

4. Environmental Resistance

A robust design is essential, as inspection robots frequently operate in dusty, wet, or extreme temperature environments. Slip rings with appropriate sealing and protective features ensure long-term reliability.

5. Low Torque

Minimal torque slip rings allow smooth and precise rotation of cameras and sensor modules. This feature is essential for controlled movement and accurate positioning in robotic inspection systems.

What Is the Best Slip Ring for Inspection Robots?

Servotecnica’s SVTS A Series slip rings are ideal for inspection robot applications, with the SVTS A 06 particularly beneficial for cameras.

The SVTS A Series features compact capsule slip rings engineered for inspection robots, specifically those equipped with cable reels and robotic camera systems. Key benefits include:

- Compact Slip Ring Design: Suitable for space-constrained applications, these slip rings feature a compact form factor without compromising functionality.

- Reliable Signal Transmission: Designed to enable stable transfer of power, video, and data signals with minimal interference.

- Durable Construction: Built to operate under continuous rotation and demanding conditions typically found in inspection and robotic systems.

- Multi-Circuit Flexibility: Capable of transmitting multiple signal types, including power, data, and video, within a single unit to support complex system architectures.

- Environmental Resistance: Constructed to maintain performance in environments exposed to dust, moisture, or temperature fluctuations.

These attributes make the SVTS A Series ideal for robotic cable reels and cameras, enabling smooth, continuous rotation by eliminating cable twisting and maintaining uninterrupted signal transmission.

The SVTS A 06 is a capsule slip ring model within the SVTS A Series, known for its compact dimensions. It is designed to transmit power and a range of signals, making it suitable for robotic cameras. The slip ring ensures low electrical noise and stable signal integrity, supporting reliable transmission of video, sensor, and high-frequency signals for inspection applications. Common uses include sewer inspection robots, pipeline monitoring systems, and turbine blade inspection tools, where consistent and efficient performance is essential.

Final Thoughts on Slip Rings for Inspection Robots

Slip rings are essential components in modern inspection robots. They enable smooth, continuous rotation of sensors, cameras, and cable reels while maintaining reliable electrical connections. The SVTS A Series, particularly the SVTS A 06, offers an ideal combination of compact design, electrical performance, and ruggedness.

Discover how Servotecnica’s slip rings help optimize the performance of inspection robots in demanding industries such as energy, infrastructure, rescue operations, and mining.