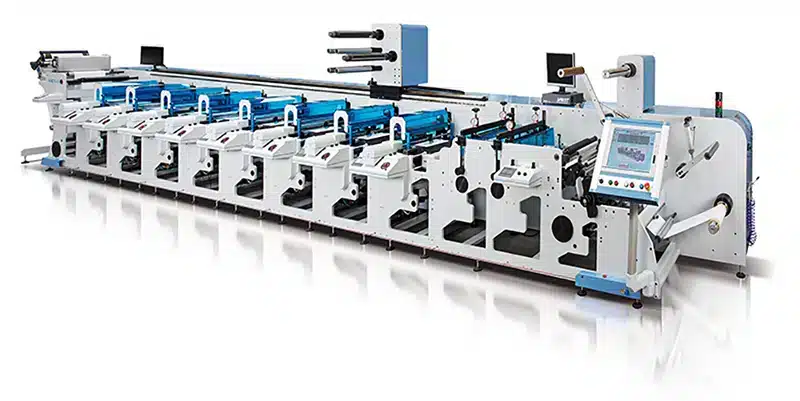

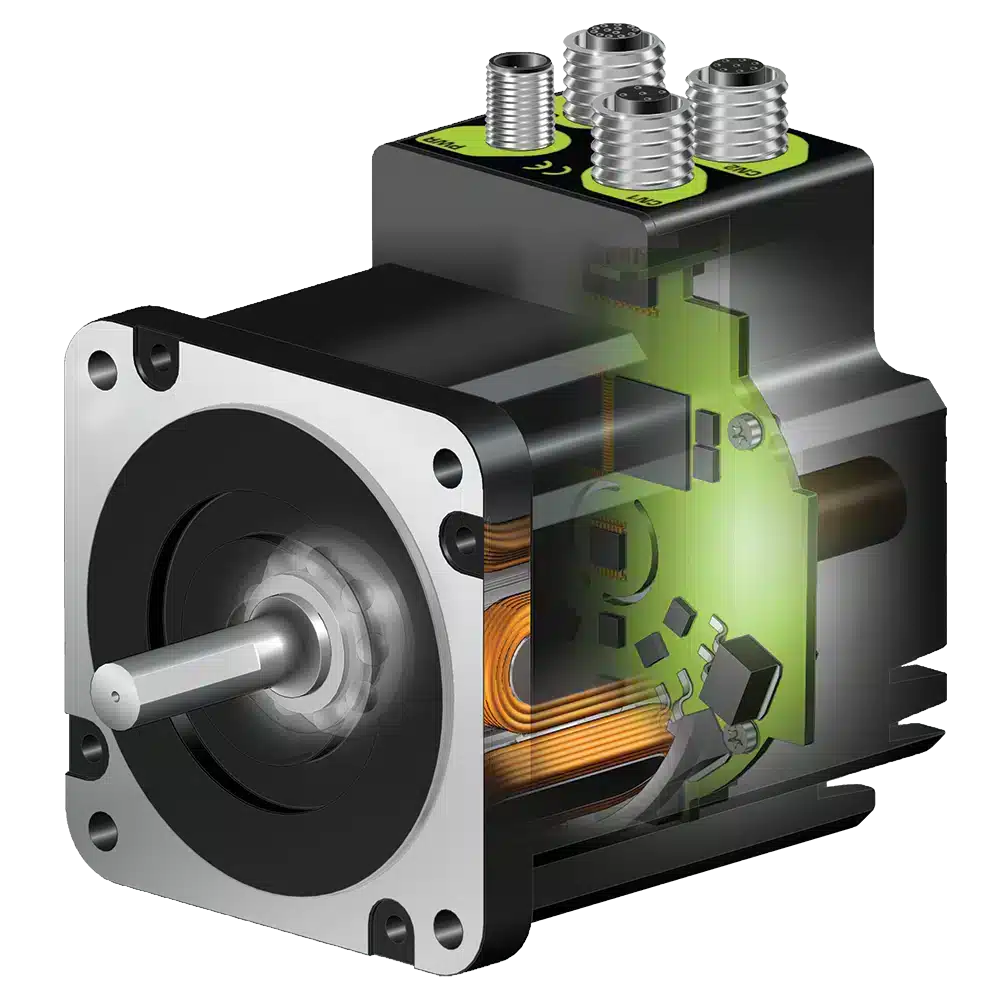

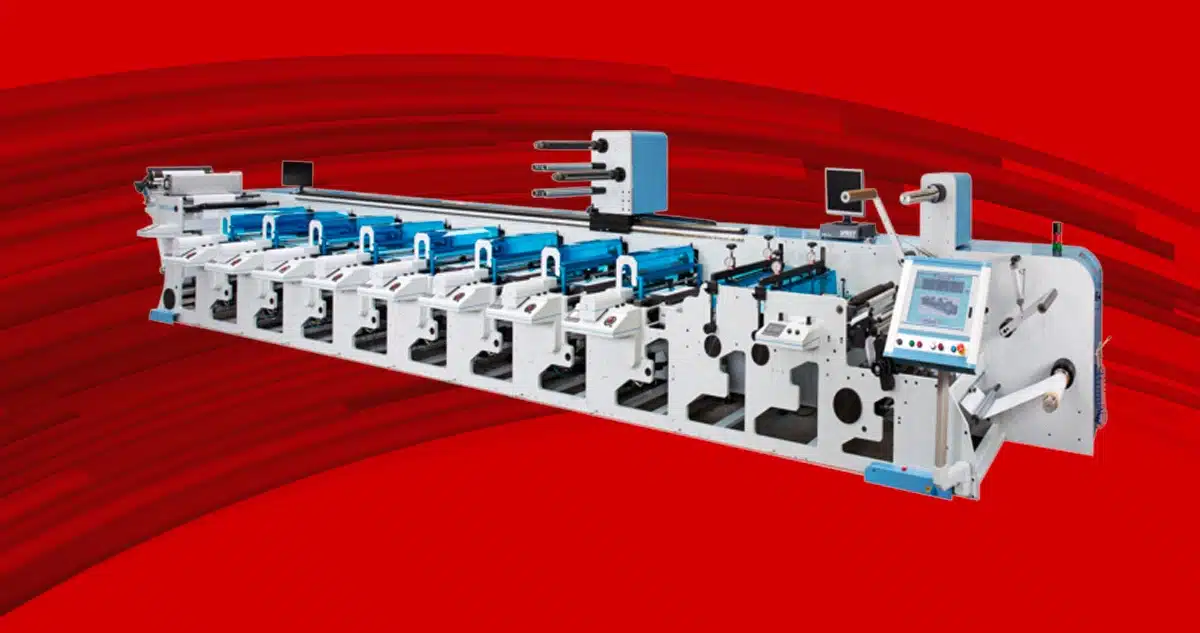

Flexographic printers have a cliché and a register for each colour. The cliché reaches the correct printing position by means of two stepper motors with integrated […]

Flexographic printers have a cliché and a register for each colour. The cliché reaches the correct printing position by means of two stepper motors with integrated electronics. The said automatic positioning means that technicians are not required to intervene for every format change. The fact that the engine has a multi-turn absolute encoder means that it does not require resetting before each restart, greatly simplifying the start-up functions.

In a small space, integrated electronics enable an interface via Profinet with the PLC placed directly on the machine, optimising and simplifying wiring. Profinet also enables simultaneous synchronisation of all devices on the network, all of which means higher quality and precision printing. The motors are also equipped with a holding brake and IP65 protection. IP65 protection provides complete protection for the motors, including protecting them from external agents always present in production environments.