The new generation Flowpack machines must combine flexibility and reduced costs; the LSIS system solves these problems by providing a complete package, from HMI and PLC […]

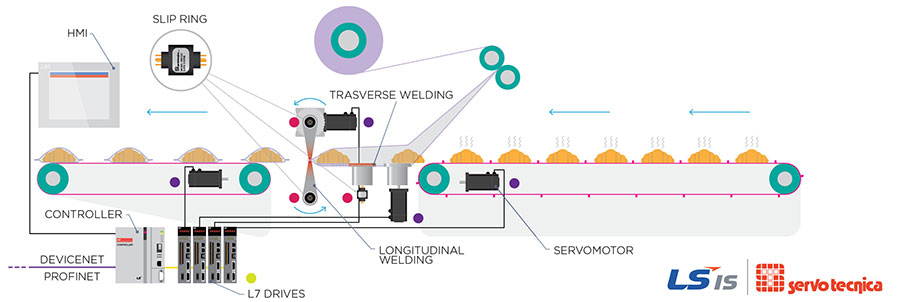

The new generation Flowpack machines must combine flexibility and reduced costs; the LSIS system solves these problems by providing a complete package, from HMI and PLC to the servomotors based on EtherCAT fieldbus.

The use of EtherCAT means the high bandwidth of 100Mbps and a flexible digital system can be used and, therefore, very short reaction times can be achieved, which allow format changes on the fly, thus avoiding unnecessary waste of material.

There are many modules for the PLC, including:

- I / 0 digital and analogue

- Thermocouple and temperature control modules

- ProfiNET and DeviceNET interfaces

- HMI interfaces of different sizes

which make it possible to satisfy the various application requirements covering a wide range of solutions, from simple 3-axis machines up to the most complex machines with tens of movements; all maintaining cycle times below a millisecond.

The compactness of the L7 series drives with power supply, braking resistor, integrated digital and analogue I/0, reduced control cabinet size and installation time.

Touch probe function means dimensions can be captured on the fly guaranteeing precision in the sealing of material used for packaging.

The wide range of brushless servomotors with incremental or absolute high resolution encoders, provides accurate position control and stability even at low speeds.

The new range of Pegasus series servo motors with integrated electronics and EtherCAT fieldbus also makes a further reduction in the size of the electric panel possible along with simplified wiring thus reducing costs and installation time.

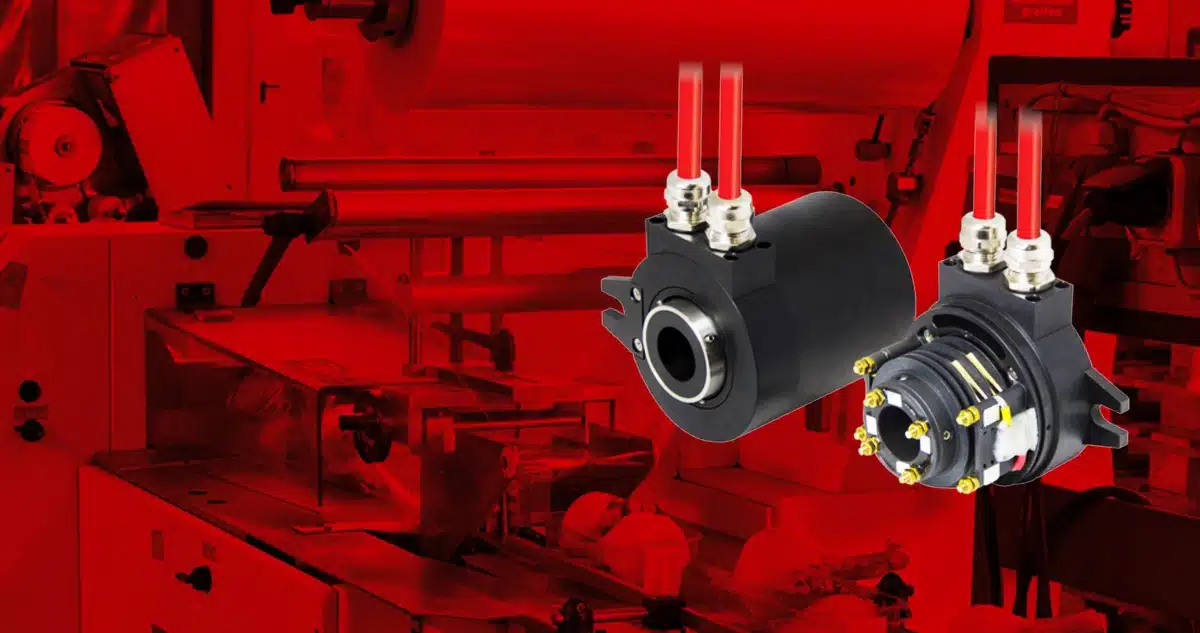

Servotecnica also supplies the SVTS E IP65 Slip Ring, which is cost-effective and maintenance-free and feature metal-on-metal technology to power resistors and read the temperature sensors on the rotating sealing blades.