Put motion control where the work is done A wiring-free cabinet allows designers of automated systems a greater degree of freedom. Now you can build a […]

Put motion control where the work is done

A wiring-free cabinet allows designers of automated systems a greater degree of freedom. Now you can build a higher-performing automated production system that almost perfectly meets motion requirements.

Motion control systems with a decentralized structure contribute to a new generation of open, modular, and flexible machines.

Cabinet-free technology is designed to allow control systems to be inserted wherever it is most useful to the machine.

Per decenni, il quadro elettrico è stato un elemento centrale nella progettazione di molti sistemi di produzione automatici. In alcuni casi, il cabinet è diventato “l’asse” intorno al quale si costruiva (spesso forzatamente) il sistema.

This is changing thanks to a new generation of Motion Control and Servo Drives. The change is not only due to the use of motors with integrated electronics, but it is the entire range of decentralized components that can be used to satisfy even the most complex motion requirements.

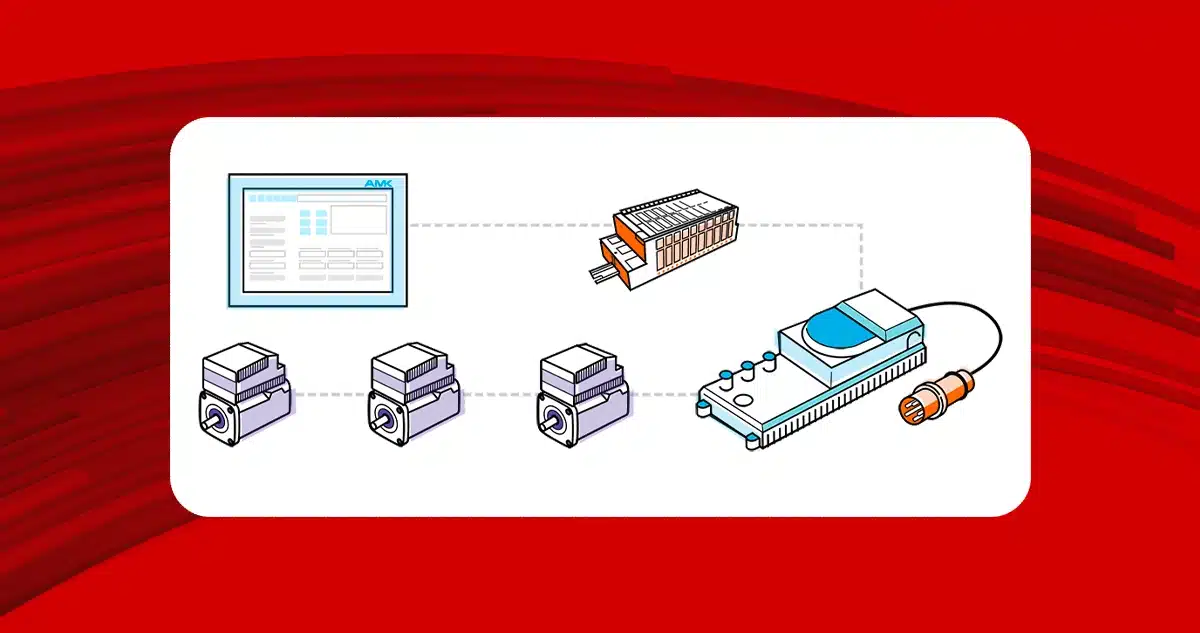

An example of a configuration

The advantages of a decentralized system:

- Positioning of drives and servo motors near each moving axis to meet any motion requirement

- Reduction/elimination of hardware costs attributable to control cabinet and cooling systems

- Simplified wiring to reduce installation costs and time

- Creating a modular automation system that can be easily reconfigured in response to any necessary changes