Why companies should create lasting relationships with universities Collaboration between industry and academia has always been a topic that is both interesting and complex. As a […]

Why companies should create lasting relationships with universities

Collaboration between industry and academia has always been a topic that is both interesting and complex. As a result of the rapid evolution of the market and the continuous metamorphosis of academia, it is now more than ever a topic of interest to companies.

Servotecnica has always considered collaboration with research institutes and universities of excellence, such as IIT, the Polytechnics of Milan, Turin, and Trento. Still, also Sant’Anna University and so on are of great value. In these collaborations, benefit and corporate mission compete as drivers of the project; while having access to the latest research results and innovative technologies is of unquestionable value, we believe it is a moral duty for companies to take charge of the practical training that universities, by their nature, cannot offer directly.

Beyond the concrete results of these experiences-usually sponsored by companies-we believe it is interesting the diversity of approaches that distinguishes the two business models, both of which are valid and potentially mutually beneficial when mixed. Companies often prefer more empirical methodologies, dropped into specific applications, whereas universities prefer more theoretical and universal models. Which way is the right way? The answer is that it depends. These collaborations can find new ways and, at best, increase efficiency.

However, the path to fruitful university-business collaboration is not without its difficulties. Given the diversity of the two business models, converging investment on a common goal is important. Universities are aimed at the education of people, the creation of new knowledge, and the excellence of that acquired. Otherwise, companies focus on overcoming the challenges of a competitive environment and aim to succeed in the marketplace.

An advantage for universities and companies

When starting a partnership, it is normal to create expectations from the partner: companies look for lessons in innovation, know-how, and high-level education, while universities expect a chance for their students to connect with the real market with internships and other opportunities that encourage professional growth. Both sides thus have specific interests. We believe a win-win situation is achieved when students well-trained in the new methodologies meet companies that can transfer these skills to real projects.

Typically, companies that do not acquire these skills grow more slowly. They miss timely access to the latest research and methodologies, resulting in longer and more tumultuous development times.

Last but not least, l’esclusione dal mondo accademico, porta le aziende a risultare meno attrattive per gli studenti più talentuosi, in un mondo dove le competenze di alto valore sono uno degli asset aziendali principali.

The collaboration with Gimatic and the Politecnico di Milano.

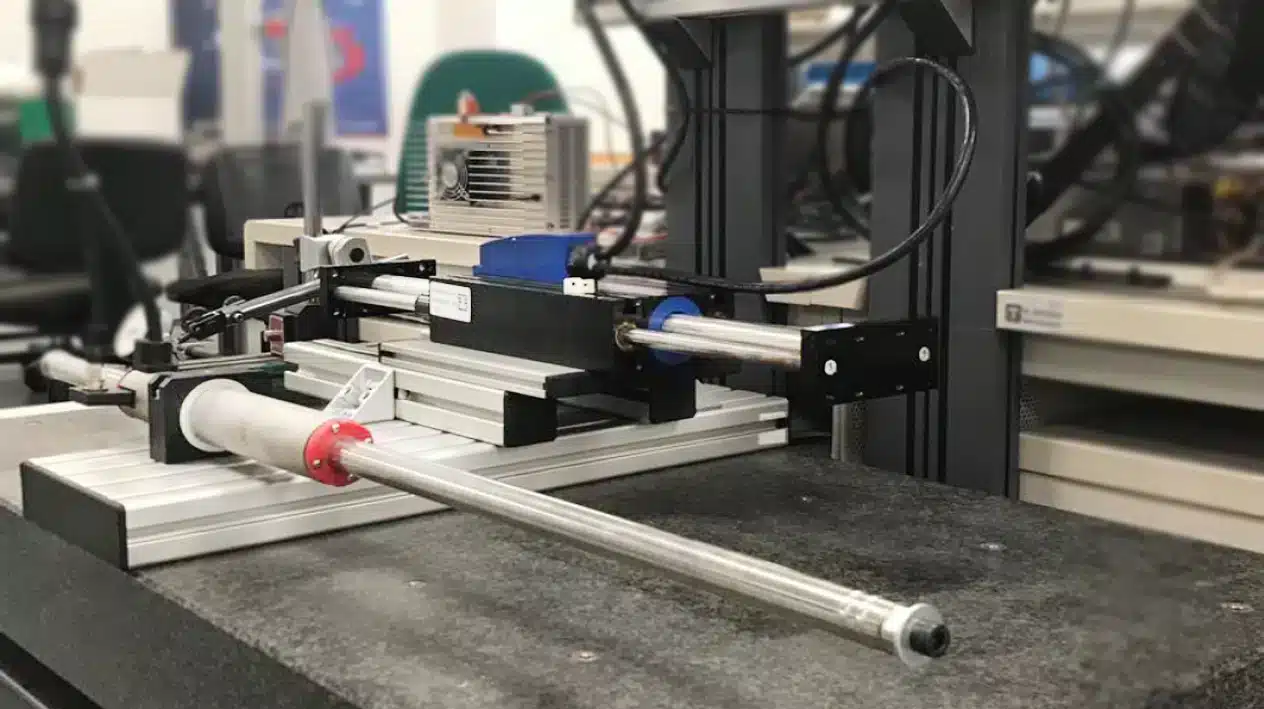

As a result of the relationship created by working with Gimatic on the Gripper application, our interest in one of the most innovative products in their catalog grows the ML linear motor series. Thus began the search for a competitive system solution with tubular geometry linear motors. The research theme is the characterization and optimization of a system composed of a tubular motor, feedback, and drive through a reliable mathematical model that allows its study to improve motor performance. Looking for a strategic partner for this activity, we learned about ProjectWork, a program promoted by the Bachelor of Science in Automation Engineering at the Politecnico di Milano, aimed at creating a communication channel between the university and companies. Offers of collaboration with PoliMi vary in cost, time, and resources involved. The most common form is the thesis paper, in which the company presents a project via a lecturer/tutor. While advantageous in purely cost-effective terms, commissioning the research to one person for a period limited to 6 months is likely to result in an unsatisfactory outcome for the company. Another type is the research contract, where the company commissions the project from the university, which, following a prior analysis, defines the time and cost of development. This approach has a higher success rate, albeit more financially burdensome. ProjectWork fits the two modes, with a 6-month duration and more people involved. The system In collaboration with Gimatic, we then presented the project “Characterization and optimization of the solution composed of incremental feedback/Gimatic linear motor/Copley Control drive” to obtain a mathematical model of the system.

The use of a linear motor with direct coupling was dictated by the need to free ourselves from modeling mechanical parts (transmissions, couplings, etc.). This would have forced us to handle an elastic component, negatively affecting the system’s rigidity. In addition, the variables introduced would have made modeling more complex and difficult without, on the other hand, constituting value in achieving our goal: to increase the efficiency of the linear motor by acting on feedback and control.

The choice of the Copley drive followed an evaluation of the performance offered in the market, having proven particularly suitable for this type of control.

The structure of the project

The ProjectWork, coordinated on the Polytechnic side by Prof. Luca Bascetta and on the Servotecnica side by engineers Giacomo Parigi and Riccardo Francazi, was espoused by 15 students from the Automation Engineering course, who were successively divided into working groups.

With a view to efficiency and fostering a positively competitive yet challenging climate for students, the groups worked on the project in parallel. Results were shared during timed meetings to foster the exchange of information necessary for achievement.

A complete system on which to operate and perform tests was then made available to the polytechnic. During the first phase, we met with the future engineers every week at a laboratory at the university. Later, at a more advanced stage, we held meetings at our headquarters to speed up the process.

At the end of the Project Work, which began in September 2017 and ended in February 2018, individual groups submitted their projects, including reports, reports, and mathematical models (developed through Matlab and Simulink).

Since this was a university project, however extraordinary, at the end of the course, each group was evaluated with the results obtained and the methods pursued. This made it a fully-fledged examination included within the curriculum.

The advantages of mathematical modeling in servo systems

Industrial manufacturing plants using automation of any kind are vulnerable to downtime that can originate from errors in design or incorrect operating logic. Considering that a medium- to long-term downtime will likely result in losing a business opportunity, an a priori analysis of the servo system structure is critical to identify any weaknesses or unwanted outputs. Ex ante analysis of the dynamic performance of a system is now possible through predictive mathematical models.

Starting with budget and technology level, using the mathematical model allows the development of challenging engineering systems that, while represented with mathematical simplicity, maintain a good degree of fidelity when equated with the physical system.

This agile approach to understanding the physical laws and underlying mathematical equations needed to evaluate system behavior also allows different configurations to be compared, making it possible to evaluate quickly and supported by data.

Modeling also allows values such as torque and resonance to be tested and to break down the system into multiple segments while maintaining a holistic view of the whole. This allows different teams to work simultaneously on complex projects, improving efficiency and lowering development costs.

The broad spectrum of industrial use of mathematical modeling also makes it instrumental in determining the proper sizing of the servosystem with the required life cycle.

Dropping this approach into the Servotecnica world, the use of specific software for mathematical modeling (such as Matlab, Simulink, and others) makes it possible to drastically reduce time and costs during the design phase by simulating servo systems that no longer have to be physically tested during development, but only during validation. The model improves pre and after-sales choice support by observing the system’s behavior when integrated into the customer’s machine. Nonetheless, such activity is appreciated by manufacturing, which receives key insights for its R&D.

The mathematical model

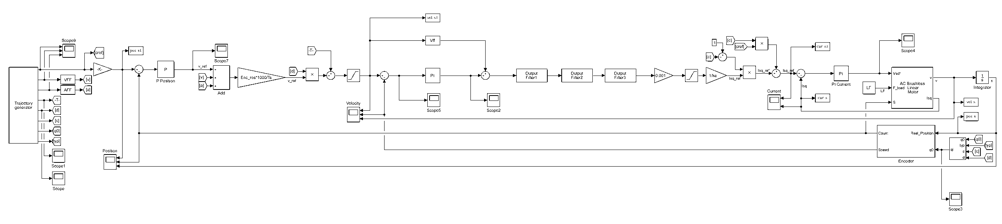

At the end of the project work, we obtained the mathematical model (fig. 1) of the entire system.

The model was then divided into sections and validated on the real system. Both simulated and real systems were stressed with different profiles and driving methods (p. in current, velocity, and position). Then the results were compared.

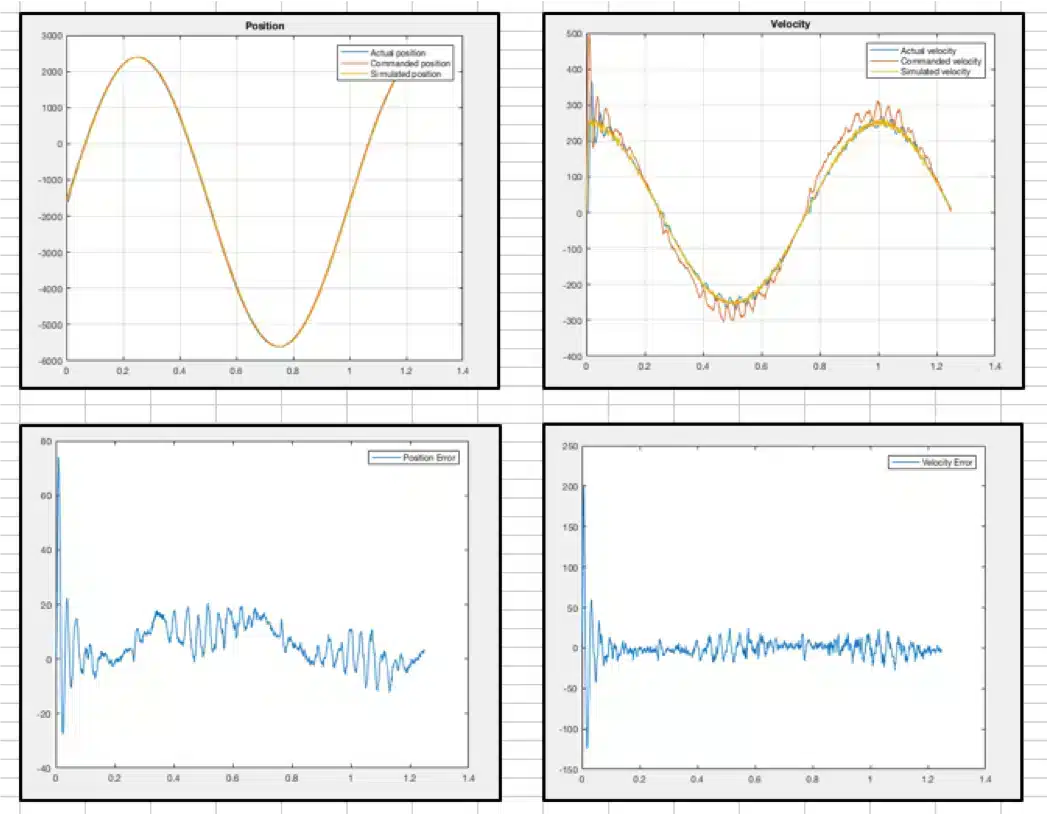

An example of the response of the position- and velocity-controlled systems with their respective errors can be seen in the following images (fig. 2), with a comparison between simulated and real sinusoids.

Social capital

As with any project, one of the most important assets for a company is its relationships with its partners, whether prior or ongoing, made stronger as it goes along. These relationships built over years of success and common goals, which go by the name of social capital, served as a lubricant with the parties involved throughout the duration of the project, a key variable in acquiring the information needed to model the system.